The great state of Colorado requires a physical inspection of any trailer purchased as a kit before it can be licensed. The inspection must be performed by an officer of the state highway patrol, by appointment only, at a regional office. This provided an opportunity to get the boat out of the driveway for the first time. The trailer is from Trailex, a manufacturer specializing in light weight aluminum trailers for small boats and kayaks. The model I chose is designed for small boats between 350 and 500 pounds. SUT-500 is the model number. After towing the boat for the first time, I must say I was very impressed with the trailer which weighs only 170 pounds. You hardly notice it's there.

Now I'm ready to join the line at the Bureau of Motorized Vehicles...

Tuesday, September 26, 2017

Friday, September 1, 2017

Her name is Melissa...

We have named the boat Melissa, derived from the Greek name for honey bee, and she sits patiently in the garage as I procrastinate. I will blame my lack of progress on the work I do for a living, however, it is more honest to say I'm basically lazy and easily distracted. This being said, we are finally close to actually putting her in the water.

A friend recently told me "you clearly like building more than sailing". I'm not sure this is true, but I'm looking forward to finding out. So far, the devil has proven to be in the details, and the details are many. One detail involved the fabrication of under deck blocks for the halyards. I used sheaves purchased from Harkin and made the blocks from Pau Ferro, a dense South American hardwood. The Pau Ferro was purchased back in the 1980's from a local lumber yard. These days Pau Ferro is often used for guitar/bass fingerboards, as a replacement for more expensive rosewood or ebony. I also used Pau Ferro for the gaff and boom jaws, as well as the mast collar. It is quite lovely to work with, but can cause an allergic reaction in some folks.

The blocks are mounted below deck (inverted) to direct the halyards towards the cockpit. The halyards pass through holes in the mast collar. (shown below)

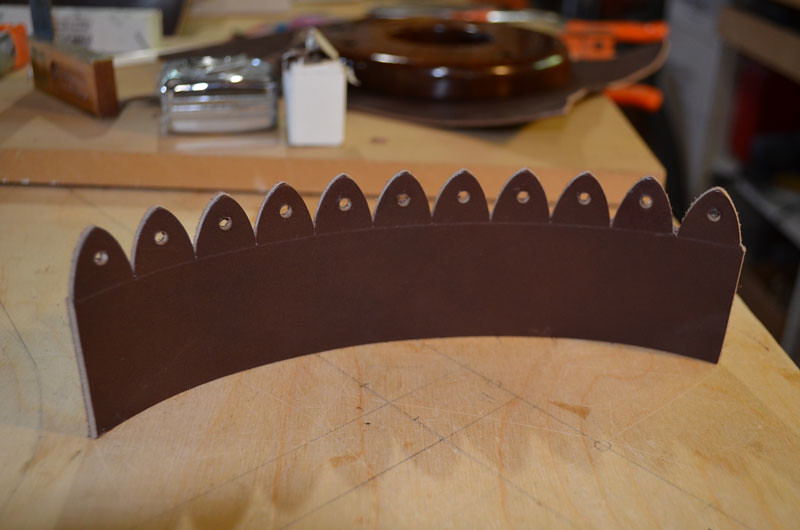

Another detail involves leather, a material I had no experience working with. I originally thought I could find a local saddle maker to help out. Someone I could pay to avoid another learning curve. This proved too difficult, so I followed the advice of Brian Toss and ordered some 7oz brown latigo. With the additional purchase of a punch, to make pretty tabs, I was ready to give leather work 101 a try.

I started with the easiest task, leather for the mast collar.

Kinda fun actually...

I didn't have any round head screws on hand, so I temporarily used flat heads. I'll change them out when my next hardware order arrives.

Other details include a bolster for the throat halyard. Pau Ferro again.

Hounds cheeks (mahogany) to support the boom when the sail is down.

Bronze chain plates. Another interesting departure from woodworking.

Forestay chain plate.

Finished mast.

The hatch frame, like the mast collar, can be easily removed for maintenance.

The hatch frame is African mahogany, like the coming.

I also used African mahogany to fabricate brackets for stowing the oars. This African mahogany is noticeably lighter in weight than the genuine mahogany.

The top of the centerboard trunk is removable. I saved an especially nice piece of mahogany for this purpose.

This block is another unnecessary detail that seemed like a good idea at the time.

This image was taken while laying out the floor boards. I'm using vertical grain red cedar, very light in weight and durable.

Western red cedar for the floor boards. I love the scent, but not the splinters.

Oar lock mounts are another detail left to the builder.

The process of leathering the boom and gaff jaws was easier than expected. I finished with three coats of marine tallow.

Finished boom and gaff. The oars are from Shaw and Tenney.

The details seem endless at times, but gradually the list grows shorter. I invested in a heavy duty swage tool to fabricate the stays, probably a waste of money, but the right tool for the job.

I'm using 3/32" stainless wire, instead of the 1/8" wire specified by the plans. In retrospect, I should probably be using spectra or the like. Some builders believe the stays are actually unnecessary. I don't know, but I'm going with a slightly lighter wire.

A friend recently told me "you clearly like building more than sailing". I'm not sure this is true, but I'm looking forward to finding out. So far, the devil has proven to be in the details, and the details are many. One detail involved the fabrication of under deck blocks for the halyards. I used sheaves purchased from Harkin and made the blocks from Pau Ferro, a dense South American hardwood. The Pau Ferro was purchased back in the 1980's from a local lumber yard. These days Pau Ferro is often used for guitar/bass fingerboards, as a replacement for more expensive rosewood or ebony. I also used Pau Ferro for the gaff and boom jaws, as well as the mast collar. It is quite lovely to work with, but can cause an allergic reaction in some folks.

The blocks are mounted below deck (inverted) to direct the halyards towards the cockpit. The halyards pass through holes in the mast collar. (shown below)

Another detail involves leather, a material I had no experience working with. I originally thought I could find a local saddle maker to help out. Someone I could pay to avoid another learning curve. This proved too difficult, so I followed the advice of Brian Toss and ordered some 7oz brown latigo. With the additional purchase of a punch, to make pretty tabs, I was ready to give leather work 101 a try.

I started with the easiest task, leather for the mast collar.

Kinda fun actually...

I didn't have any round head screws on hand, so I temporarily used flat heads. I'll change them out when my next hardware order arrives.

Other details include a bolster for the throat halyard. Pau Ferro again.

Hounds cheeks (mahogany) to support the boom when the sail is down.

Bronze chain plates. Another interesting departure from woodworking.

Forestay chain plate.

Finished mast.

The hatch frame, like the mast collar, can be easily removed for maintenance.

The hatch frame is African mahogany, like the coming.

I also used African mahogany to fabricate brackets for stowing the oars. This African mahogany is noticeably lighter in weight than the genuine mahogany.

The top of the centerboard trunk is removable. I saved an especially nice piece of mahogany for this purpose.

This block is another unnecessary detail that seemed like a good idea at the time.

This image was taken while laying out the floor boards. I'm using vertical grain red cedar, very light in weight and durable.

Western red cedar for the floor boards. I love the scent, but not the splinters.

Oar lock mounts are another detail left to the builder.

The process of leathering the boom and gaff jaws was easier than expected. I finished with three coats of marine tallow.

Finished boom and gaff. The oars are from Shaw and Tenney.

The details seem endless at times, but gradually the list grows shorter. I invested in a heavy duty swage tool to fabricate the stays, probably a waste of money, but the right tool for the job.

I'm using 3/32" stainless wire, instead of the 1/8" wire specified by the plans. In retrospect, I should probably be using spectra or the like. Some builders believe the stays are actually unnecessary. I don't know, but I'm going with a slightly lighter wire.

Subscribe to:

Comments (Atom)