The rough surface will be finish sanded before applying varnish.

I will need to flip the boat and paint the bottom before installing the coaming and hatch. The centerboard and rudder foil will also be painted to match the hull.

The rudder has been an interesting project. In keeping with my tendency to make things more difficult, I decided on a retractable rudder instead of the simple barn door type specified in the plans. To this end I added a retractable foil, keeping the general shape and size of the barn door arrangement when the foil is up. The foil is manipulated by a single line, in the form of a loop running up through the tiller, and attached to the foil at both ends. (the small holes)

The foil will pivot on 1 1/2" round high molecular weight polyethylene. The white colored material is epoxy strengthened with silica. Before the foil was glassed I drilled oversized holes and poured the epoxy. After the epoxy cured the foil was glassed and the actual holes drilled, creating a hard waterproof barrier.

The finished product.

The foil is shaped like a pulley at the top to accommodate the control line.

The pivot rod is attached to the rudder housing, shown below, with a 1/4" carriage bolt. The housing must be water tight, so all surfaces are glassed. I had to do this in steps. The center layer is 3/4" mahogany with glass on both sides. The outer pieces are 3/8" mahogany, also glassed on both sides. The center layer contains two 1/2" x 1/2" channels for the control lines as well as two sheaves to redirect these lines. These can be seen below.

After sealing the channels with 3 coats of epoxy I applied cover strips and another layer of fiberglass. Now I'm ready to glue on the other side.

Another view of the internals.

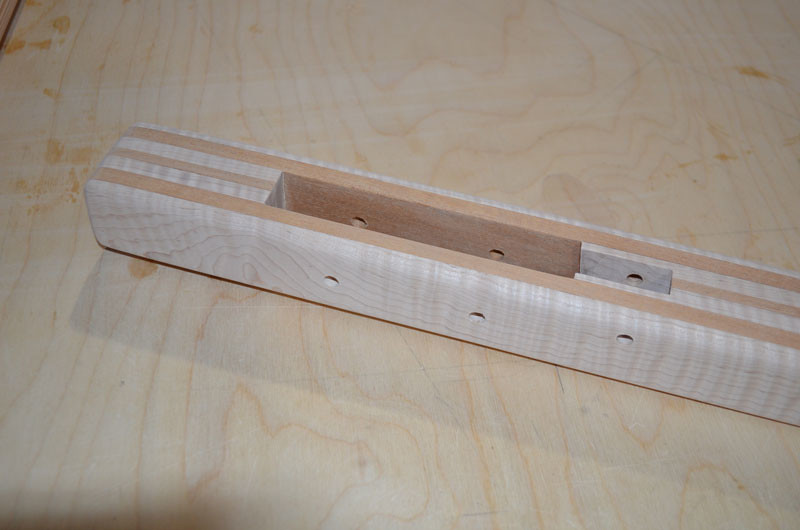

The tiller attaches to the tenon shown below.

I had some nice maple laying around which I combined with mahogany for the tiller.

The slots seen on the top will accommodate sheaves for the foil control lines.

A closer view from the top.

My next chore was to fabricate the boom and gaff spar. Both are solid Douglas Fir and tapered. This provided a chance to have some fun with my hand plane.

I was very lucky to find such wonderful straight grained material locally.

The boom (shown below) is 11' 6" in length and tapers from 1 1/2" to 1 1/8". The gaff spar is 8' in length, tapering from 1 3/8" to 1".

Both have wooden jaws that fit around the mast. However, the angle of the gaff spar requires a slightly different shape.

I used a very hard wood, known as Pau Ferro or Morado, for the jaws. This wood comes from South America and is very durable.

Next up, paint the hull... oh boy!