We are lucky to have good sailing water only five miles from our home. Union reservoir, actually a natural lake, is managed by the city of Longmont, CO and allows only motorless craft. The lake is roughly a mile in width and length and has a max depth of 28 feet. The water is warm by Colorado standards and the view of the back range is superb.

I've been chomping at the bit to get Melissa in the water, but under the right conditions, and yesterday was almost perfect. My son Quinn had the day off and volunteered to assist. We arrived at 1PM expecting the wind to pick up around 2PM. The forecast was for mild 4 to 5 mph winds from the SE throughout the afternoon. However, it was dead calm when we put the boat in the water.

Now all we needed was a breeze. I was happy to see the trim looked good with nobody aboard.

My wife made plans to join us but hadn't yet arrived when a very mild wind finally came up, just a few puffs at first, but enough to get us sailing. When I first stepped aboard I was surprised by the stability considering the beam is only 64 inches. We hoisted the sail and ghosted away from the dock. As novices, we spent the next couple hours puttering around and getting a feel for the basics. Occasionally the wind would pick up a bit and put a smile on our faces. The boat does quite well in light airs and was relatively nimble with a 3 to 5 mph wind. This boat should be really fun in 7 to 10 mph winds.

Some kind folks from Estes Park took a few pics as they sailed by. You can see how nice the view is.

I love the look of a gaff rig.

90 square feet of sail seems just about right as the boat moves easily in a mild breeze.

Around 4PM the mild winds began to dissipate and we headed back to the dock. I was kind of amazed how well the boat pointed in the very mild breeze.

As we approached the dock I scandalized the sail and took out the oars. What ensued can only be described a Laurel and Hardy moment.

The guy in the other boat was laughing his ass off. Eventually we got her to the dock.

A successful, and slightly boring, maiden voyage comes to an end. I can't wait to try her out in better winds.

The proverbial 'Miller Time'

Tim's Melonseed Build

Thursday, September 27, 2018

Monday, September 17, 2018

Sail On...

After ten months in a comma I awakened just in time to prepare for the 2018 Wooden Boat Show in Port Townsend ,WA. The very idea of building a boat was the result of our first visit to Port Townsend way back in 2011. This is our third trip to the show and our first opportunity to bring a boat. The following images show the sail up for the first time. The sail is not yet adjusted properly, but it fits well and the excellent workmanship of the sail maker is evident.

Stuart, of Dabbler Sails, really knows his stuff and was a pleasure to deal with.

The halyards are secured with old style belay pins.

Oars are easily accessible and secured with quick release bungee straps.

Oarlocks are stowed in leather pouches underneath the deck.

Time to prepare her for the 1400 mile trip to Port Townsend.

Having a good time at the 42ad wooden boat festival in Port Townsend, WA.

Stuart, of Dabbler Sails, really knows his stuff and was a pleasure to deal with.

Oars are easily accessible and secured with quick release bungee straps.

Oarlocks are stowed in leather pouches underneath the deck.

Time to prepare her for the 1400 mile trip to Port Townsend.

Having a good time at the 42ad wooden boat festival in Port Townsend, WA.

Tuesday, September 26, 2017

Almost legal...

The great state of Colorado requires a physical inspection of any trailer purchased as a kit before it can be licensed. The inspection must be performed by an officer of the state highway patrol, by appointment only, at a regional office. This provided an opportunity to get the boat out of the driveway for the first time. The trailer is from Trailex, a manufacturer specializing in light weight aluminum trailers for small boats and kayaks. The model I chose is designed for small boats between 350 and 500 pounds. SUT-500 is the model number. After towing the boat for the first time, I must say I was very impressed with the trailer which weighs only 170 pounds. You hardly notice it's there.

Now I'm ready to join the line at the Bureau of Motorized Vehicles...

Now I'm ready to join the line at the Bureau of Motorized Vehicles...

Friday, September 1, 2017

Her name is Melissa...

We have named the boat Melissa, derived from the Greek name for honey bee, and she sits patiently in the garage as I procrastinate. I will blame my lack of progress on the work I do for a living, however, it is more honest to say I'm basically lazy and easily distracted. This being said, we are finally close to actually putting her in the water.

A friend recently told me "you clearly like building more than sailing". I'm not sure this is true, but I'm looking forward to finding out. So far, the devil has proven to be in the details, and the details are many. One detail involved the fabrication of under deck blocks for the halyards. I used sheaves purchased from Harkin and made the blocks from Pau Ferro, a dense South American hardwood. The Pau Ferro was purchased back in the 1980's from a local lumber yard. These days Pau Ferro is often used for guitar/bass fingerboards, as a replacement for more expensive rosewood or ebony. I also used Pau Ferro for the gaff and boom jaws, as well as the mast collar. It is quite lovely to work with, but can cause an allergic reaction in some folks.

The blocks are mounted below deck (inverted) to direct the halyards towards the cockpit. The halyards pass through holes in the mast collar. (shown below)

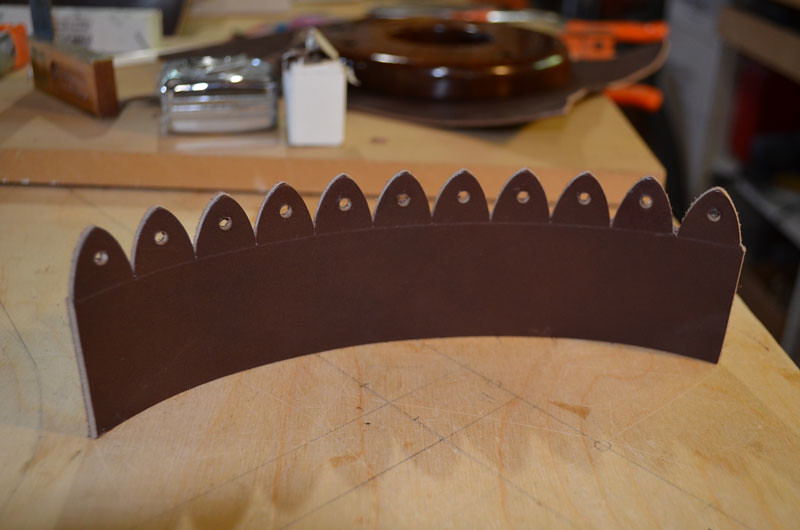

Another detail involves leather, a material I had no experience working with. I originally thought I could find a local saddle maker to help out. Someone I could pay to avoid another learning curve. This proved too difficult, so I followed the advice of Brian Toss and ordered some 7oz brown latigo. With the additional purchase of a punch, to make pretty tabs, I was ready to give leather work 101 a try.

I started with the easiest task, leather for the mast collar.

Kinda fun actually...

I didn't have any round head screws on hand, so I temporarily used flat heads. I'll change them out when my next hardware order arrives.

Other details include a bolster for the throat halyard. Pau Ferro again.

Hounds cheeks (mahogany) to support the boom when the sail is down.

Bronze chain plates. Another interesting departure from woodworking.

Forestay chain plate.

Finished mast.

The hatch frame, like the mast collar, can be easily removed for maintenance.

The hatch frame is African mahogany, like the coming.

I also used African mahogany to fabricate brackets for stowing the oars. This African mahogany is noticeably lighter in weight than the genuine mahogany.

The top of the centerboard trunk is removable. I saved an especially nice piece of mahogany for this purpose.

This block is another unnecessary detail that seemed like a good idea at the time.

This image was taken while laying out the floor boards. I'm using vertical grain red cedar, very light in weight and durable.

Western red cedar for the floor boards. I love the scent, but not the splinters.

Oar lock mounts are another detail left to the builder.

The process of leathering the boom and gaff jaws was easier than expected. I finished with three coats of marine tallow.

Finished boom and gaff. The oars are from Shaw and Tenney.

The details seem endless at times, but gradually the list grows shorter. I invested in a heavy duty swage tool to fabricate the stays, probably a waste of money, but the right tool for the job.

I'm using 3/32" stainless wire, instead of the 1/8" wire specified by the plans. In retrospect, I should probably be using spectra or the like. Some builders believe the stays are actually unnecessary. I don't know, but I'm going with a slightly lighter wire.

A friend recently told me "you clearly like building more than sailing". I'm not sure this is true, but I'm looking forward to finding out. So far, the devil has proven to be in the details, and the details are many. One detail involved the fabrication of under deck blocks for the halyards. I used sheaves purchased from Harkin and made the blocks from Pau Ferro, a dense South American hardwood. The Pau Ferro was purchased back in the 1980's from a local lumber yard. These days Pau Ferro is often used for guitar/bass fingerboards, as a replacement for more expensive rosewood or ebony. I also used Pau Ferro for the gaff and boom jaws, as well as the mast collar. It is quite lovely to work with, but can cause an allergic reaction in some folks.

The blocks are mounted below deck (inverted) to direct the halyards towards the cockpit. The halyards pass through holes in the mast collar. (shown below)

Another detail involves leather, a material I had no experience working with. I originally thought I could find a local saddle maker to help out. Someone I could pay to avoid another learning curve. This proved too difficult, so I followed the advice of Brian Toss and ordered some 7oz brown latigo. With the additional purchase of a punch, to make pretty tabs, I was ready to give leather work 101 a try.

I started with the easiest task, leather for the mast collar.

Kinda fun actually...

I didn't have any round head screws on hand, so I temporarily used flat heads. I'll change them out when my next hardware order arrives.

Other details include a bolster for the throat halyard. Pau Ferro again.

Hounds cheeks (mahogany) to support the boom when the sail is down.

Bronze chain plates. Another interesting departure from woodworking.

Forestay chain plate.

Finished mast.

The hatch frame, like the mast collar, can be easily removed for maintenance.

The hatch frame is African mahogany, like the coming.

I also used African mahogany to fabricate brackets for stowing the oars. This African mahogany is noticeably lighter in weight than the genuine mahogany.

The top of the centerboard trunk is removable. I saved an especially nice piece of mahogany for this purpose.

This block is another unnecessary detail that seemed like a good idea at the time.

This image was taken while laying out the floor boards. I'm using vertical grain red cedar, very light in weight and durable.

Western red cedar for the floor boards. I love the scent, but not the splinters.

Oar lock mounts are another detail left to the builder.

The process of leathering the boom and gaff jaws was easier than expected. I finished with three coats of marine tallow.

Finished boom and gaff. The oars are from Shaw and Tenney.

The details seem endless at times, but gradually the list grows shorter. I invested in a heavy duty swage tool to fabricate the stays, probably a waste of money, but the right tool for the job.

I'm using 3/32" stainless wire, instead of the 1/8" wire specified by the plans. In retrospect, I should probably be using spectra or the like. Some builders believe the stays are actually unnecessary. I don't know, but I'm going with a slightly lighter wire.

Thursday, September 1, 2016

A little color...

My decision to paint the exterior of the hull is purely utilitarian. Many of my friends have told me I'm crazy to not leave the hull bright. As it is I will have plenty of annual maintenance to do with the bright deck and interior. I researched the options and went with Epifanes two-part polyurethane, primarily for two reasons. Tests by Jamestown Distributors concluded it was the toughest of the products they carried and it was available in a huge range of colors. Choosing a color was difficult, in part because there were so many choices.

We will certainly be visible if the boat goes turtle. I followed the manufactures advice and applied two coats of epoxy primer, followed by three coats of polyurethane. Both products were easy to apply. I used an old high pressure spray gun at 32psi with the product thinned about 10%.

While the paint cures I'll put the trailer together and finish the spars.

We will certainly be visible if the boat goes turtle. I followed the manufactures advice and applied two coats of epoxy primer, followed by three coats of polyurethane. Both products were easy to apply. I used an old high pressure spray gun at 32psi with the product thinned about 10%.

While the paint cures I'll put the trailer together and finish the spars.

Wednesday, August 24, 2016

Bottom's up...

There is an art to everything and varnishing is no exception. My experience with varnish and a brush has been, at best, less than gratifying. I kept working at it figuring I'd get better, but it always seemed like one step forward and two steps back. I came to believe it was impossible to get a smooth and relatively dust free surface with a brush. When it was time to varnish the deck I toyed with the idea of using a spray gun, but reverted to the brush which seemed like the path of least resistance at the time. After a number of coats, six to be exact, I finally acknowledged my insanity, doing the same thing and expecting different results.

I have a twenty year old spray gun, high pressure of course, but still serviceable. So I went online looking for advice on spraying Epifanes varnish. I couldn't find much info, even at the product website. Lots of advice on brushing. One article indicated you must use Epifanes spray thinner to get the right results. Taking no chances, I acquired a quart of the spray thinner.

My initial concern was that my spray tip would be too fine for the varnish. My concern was unfounded and it took only a little experimentation to get a good spray pattern with the product thinned 50% at 32psi. As I sprayed on the first coat I kicked myself in the kester for not trying this sooner. What took an hour using the brush I can spray in ten minutes with way better results. All I can say is better late than never. I added three coats to the six applied by hand and called it good enough.

While the deck varnish cures the plan is to paint the bottom. It is time to get rid of the strongback. I cobbled together a cart with 2x6's from the local big box and added a carpet covered cradle matching the deck camber. With the help of a few strong friends and family members we extracted the boat from the garage.

We rolled the boat on an air mattress for added safety and lifted it onto the cradle. I was very pleased to find the boat was much lighter than expected.

My friends look at me incredulously when I tell them I'm painting the bottom, but they won't have to maintain all that varnish. As it is, the transom, deck, interior and stem are all bright and will require frequent maintenance. I'll be spraying the hull with Epifanes poly-urethane. Teal green, my wife's choice.

I have a twenty year old spray gun, high pressure of course, but still serviceable. So I went online looking for advice on spraying Epifanes varnish. I couldn't find much info, even at the product website. Lots of advice on brushing. One article indicated you must use Epifanes spray thinner to get the right results. Taking no chances, I acquired a quart of the spray thinner.

My initial concern was that my spray tip would be too fine for the varnish. My concern was unfounded and it took only a little experimentation to get a good spray pattern with the product thinned 50% at 32psi. As I sprayed on the first coat I kicked myself in the kester for not trying this sooner. What took an hour using the brush I can spray in ten minutes with way better results. All I can say is better late than never. I added three coats to the six applied by hand and called it good enough.

While the deck varnish cures the plan is to paint the bottom. It is time to get rid of the strongback. I cobbled together a cart with 2x6's from the local big box and added a carpet covered cradle matching the deck camber. With the help of a few strong friends and family members we extracted the boat from the garage.

We rolled the boat on an air mattress for added safety and lifted it onto the cradle. I was very pleased to find the boat was much lighter than expected.

My friends look at me incredulously when I tell them I'm painting the bottom, but they won't have to maintain all that varnish. As it is, the transom, deck, interior and stem are all bright and will require frequent maintenance. I'll be spraying the hull with Epifanes poly-urethane. Teal green, my wife's choice.

Subscribe to:

Comments (Atom)